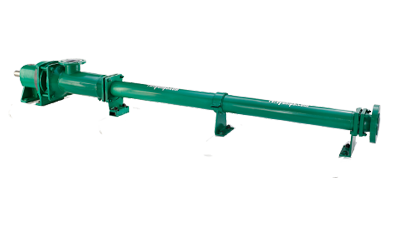

Standard PC Pump

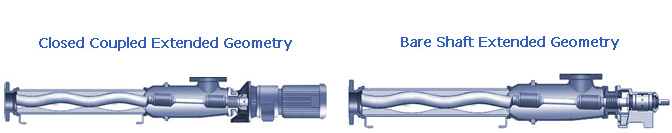

Roto Xtra Value Progressive Cavity Pumps are designed to pump ‘tough – to – handle’ fluids with ease in varied industries. The construction of these pumps is based on the modular concept and comprises of next generation pumping elements i.e. Rotor, Stator, Solid Shaft and Double Sealed Cardan Universal Joints for improved performance and longer service life.

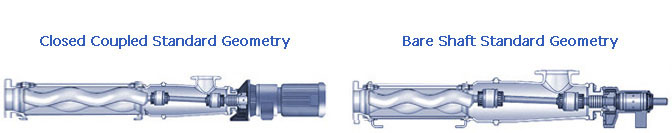

These pumps are available in bare shaft and close coupled configuration. Selected pump sizes are available with 6 stages and 8 stages.. Options also available with different material grades and shaft sealing.

Single Stage Pump

Capacity: up to 500 m3/hr

Pressure: up to 6 bar

These Heavy Duty cost effective pumps use the extended Rotor, Stator Geometry and results in lower rubbing velocities which are ideal for various applications.

Multi Stage Pump

Capacity: up to 250 m3/hr

Pressure: up to 48 bar

These heavy duty pumps are designed for continuous or intermittent duty and are suitable to perform efficiently even for the most difficult fluid handling applications in various industries.

Small Capacity ‘RD’ Series Pumps (Standard Geometry)

| Size | D41 | D43 | D45 | D47 | D49 | D51 | D53 | D55 |

|---|---|---|---|---|---|---|---|---|

| Capacity | ||||||||

|

m3/hr

|

0.11 | 0.3 | 0.6 | 1.6 | 3.5 | 6.5 | 9.5 | 17 |

|

GPM

|

0.4 | 1.3 | 2.6 | 7 | 15 | 29 | 42 | 75 |

| Pressure | ||||||||

|

Bar

|

24 | 48 | 24 | 24 | 24 | 12 | 12 | 6 |

|

PSI

|

348 | 696 | 348 | 348 | 348 | 174 | 174 | 87 |

Medium to Large Capacity ‘RM’ series Pumps (Standard Geometry)

| Size | M50 | M52 | M54 | M56 | M58 | M60 | M62 | M64 | M66 | M69 | M72 | M73 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | ||||||||||||

|

m3/hr

|

4 | 8 | 14 | 18 | 26 | 31 | 55 | 78 | 95 | 150 | 200 | 250 |

|

GPM

|

18 | 35 | 62 | 79 | 114 | 136 | 242 | 343 | 418 | 660 | 880 | 1100 |

| Pressure | ||||||||||||

|

Bar

|

48 | 48 | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 |

|

PSI

|

696 | 696 | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 |

Xtra Large Capacity ‘RL’ Series Pumps. (Extended Geometry)

| Size | L54 | 54M | L57 | 57M | L59 | 59M | 61M | L63 | 63M |

|---|---|---|---|---|---|---|---|---|---|

|

Capacity

|

|||||||||

|

m3/hr

|

14 | 18 | 25 | 31 | 42 | 51 | 56 | 70 | 86 |

|

GPM

|

62 | 79 | 110 | 136 | 185 | 224 | 246 | 308 | 380 |

|

Pressure

|

|||||||||

|

Bar

|

6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

|

PSI

|

87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 |

| Size | 65M | L67 | 67M | L71 | 69M | 71M | L75 | 73M | 76M |

|---|---|---|---|---|---|---|---|---|---|

|

Capacity

|

|||||||||

|

m3/hr

|

114 | 116 | 152 | 195 | 212 | 272 | 345 | 352 | 420 |

|

GPM

|

502 | 511 | 669 | 860 | 933 | 1198 | 1520 | 1550 | 1850 |

|

Pressure

|

|||||||||

|

Bar

|

6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

|

PSI

|

87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 |

WETTABLE HOUSING COMPONENTS:

• Cast Iron • Cast Stainless Steel • Fabricated Steel • Fabricated Stainless Steel

STATOR:

• Natural • Nitrile • High Nitrile • EPDM • Chloro-Sulphonated Rubber • Fluoroelastomer • Aflas • HNBR

ROTOR:

• Tool Steel • Case Hardened Steel • Alloy Steel • Stainless Steel

COUPLING ROD:

• Alloy Steel • Stainless Steel

SHAFT:

• Alloy Steel • Stainless Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex • Alloy 20 • Haste Alloy

ROTOR SURFACE COATINGS:

• Ceramic Coatings • Tungsten Carbide • Hard Chrome Plating

PROTECTIVE COATINGS:

• Rubber Lining • Epoxy Coatings

Dry Running Protection Device:

To prevent the stator damage due to dry running, specially developed temperature sensor is screwed into the stator wall to monitor the operating temperature. If by any chance the pump runs dry, the stator temperature would increase. Roto DRP would switch off the pump at pre set temperature.

Pressure Switch:

To prevent the pump from damage due to over pressurization in the discharge as well as low pressures beyond the capability of the pump. This system trips the pump and protects the pump as well as the system.

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

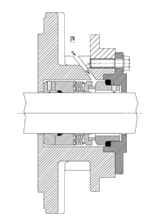

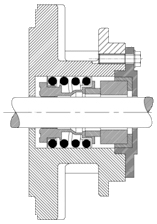

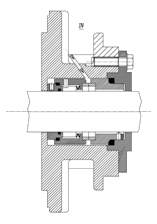

ROTO SEAL CODE ‘M’

MEDIA PROPERTIES: Low to high viscosities with solids.

APPLICATIONS: Domestic & industrial sewage treatment.

DESCRIPTION: Single acting, unbalance, single helical coil spring, elastomeric bellow seal and bi-directional.

PRESSURE RANGE: Up to 12 bar

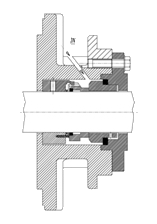

ROTO SEAL CODE ‘L’

MEDIA PROPERTIES: Low to high viscosities with solids.

APPLICATIONS: Domestic & industrial sewage treatment.

DESCRIPTION: Single acting, unbalance, single helical coil spring, elastomeric bellow seal and bi-directional.

PRESSURE RANGE: Up to 12 bar

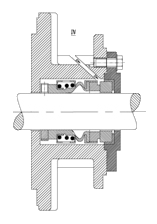

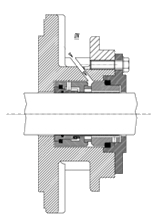

ROTO SEAL CODE ‘N’

MEDIA PROPERTIES: Containing solids or with high viscosities. e.g. sugar, paper and waste water industry.

APPLICATIONS: Oil, sewage water, clean water, corrosive Applications, oil water separation, food applications.

DESCRIPTION: Single acting, unbalance, bidirectional, wave spring.

PRESSURE RANGE: Up to 25 bar

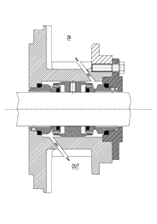

ROTO SEAL CODE ‘P’

MEDIA PROPERTIES: Containing solids or with high viscosities. e.g. sugar, paper and waste water Industry

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation, food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and wave spring.

PRESSURE RANGE: Up to 25 bar

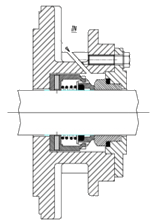

ROTO SEAL CODE ‘R’

MEDIA PROPERTIES: Containing solids or with high viscosities. e.g. sugar, paper and waste water industry

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and multiple spring.

PRESSURE RANGE: Up to 25 bar

ROTO SEAL CODE ‘S’

MEDIA PROPERTIES: Containing solids or with high viscosities. e.g. sugar, paper and waste water industry

APPLICATIONS: : Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and multiple spring.

PRESSURE RANGE: Up to 25 bar

ROTO SEAL CODE ‘T’

MEDIA PROPERTIES: Low to high viscosity, with or without solids, abrasive, adhesives, crystallizing, aggressive, toxic media.

APPLICATIONS: Toxic media, food , pharma, sewage and ceramic slurries.

DESCRIPTION: Double acting, multiple spring, unbalanced and bi-directional.

PRESSURE RANGE: Up to 25 bar

ROTO SEAL CODE ‘V’

MEDIA PROPERTIES: High temperature high viscosity.

APPLICATIONS: Refinery duties, bitumen and asphalt.

DESCRIPTION: Single acting, balance, bi-directional and metal bellow.

PRESSURE RANGE: Up to 12 bar